About Production Manager and EDGE Connect

You can add a direct connection between ProNest and a Hypertherm EDGE Connect CNC. CNC operators can view and load the current pending queue of nests from the web app directly on the CNC. Real-time machine data from the CNC are sent to ProNest and are available in Production Manager. This includes machine status and actual production time.

How it works

ProNest creates NC files of nests for cutting. These nests are tracked by ProNest Server in the database. The nests are added to the Pending queue for the EDGE Connect machine in Production Manager, where they can be prioritized, if needed. On the CNC, the EDGE Connect operator loads a nest from the top of the queue and begins cutting.

Accurate, real-time production information is sent continuously from the CNC to ProNest Server. This includes cutting machine status and production time. This information is recorded in the database and accessible in the web app.

Topology

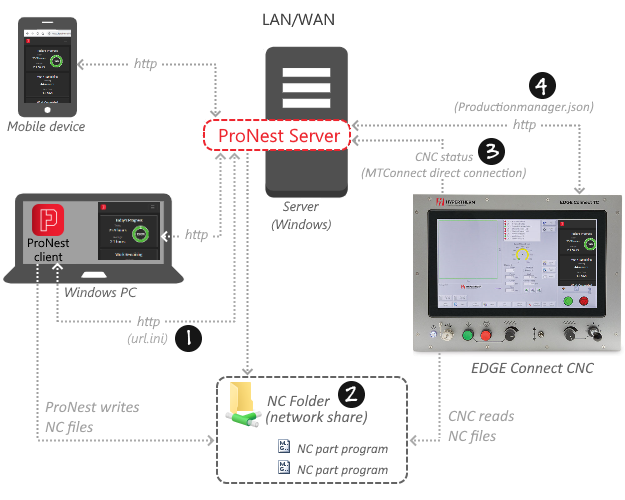

A basic topology of ProNest, ProNest Server, and the EDGE Connect CNC on an intranet.

- The ProNest client points to ProNest Server (url.ini on the client PC).

- ProNest client, ProNest Server, and the EDGE Connect CNC must have access to a common shared folder for NC part programs.

- The directly-connected Production Manager machine for EDGE Connect is set up in Production Manager and communicates via MTConnect. This enables CNC status and production information to go to ProNest Server.

- The EDGE Connect points to ProNest Server, in order to use the web app on the CNC (productionmanager.json on the CNC).